Market analysis

Magnesium alloy particles, as an important lightweight material, have seen continuous growth in demand in several industries in recent years, and the market outlook is promising. The following is a detailed analysis of the current market status, drivers and future trends of magnesium alloy particles:

1. The global magnesium alloy market size reached USD 5.5 billion in 2024, of which magnesium alloy particles accounted for about 15-20%. It is expected to increase to $9 billion by 2032. China is the world's largest producer of magnesium alloy, the production accounted for more than 80% of the world, magnesium alloy particles export volume increased year by year.

2. Main application areas

Automotive industry: used to manufacture lightweight parts such as gearbox shells and steering wheel skeletons.

Aerospace: used for manufacturing engine parts, fuselage structural parts, etc.

3C electronics: used for laptop computers, cell phone shells, etc.

Medical equipment: used to manufacture implantable instruments, surgical tools, etc.

Military industry: used to manufacture missile parts, armor materials, etc.

3. Regional distribution

China: The main production bases are located in Shanxi, Shaanxi and Ningxia.

North America: The U.S. and Canada are technologically leading in the field of high-end magnesium alloy particles (e.g. WE43).

Europe: Germany and France have strong demand in the field of automobile lightweight.

1. Lightweight trend automotive, aerospace and other industries continue to grow the demand for lightweight materials, magnesium alloy particles density is only 2/3 of aluminum, is the ideal lightweight alternative materials.

2. Environmental protection policy to promote the global requirements for energy saving and emission reduction is becoming increasingly strict, magnesium alloy particles in the automobile weight reduction, reduce fuel consumption has significant advantages.

3. technological progress of new magnesium alloy particles (such as rare earth magnesium alloy, nano-magnesium alloy) research and development to enhance the strength, corrosion resistance and processing performance of the material.

4. Cost advantage of magnesium alloy particles production costs have been declining year by year, and the cost-effectiveness gradually exceeds that of aluminum alloys and engineering plastics.

Ⅲ. The future development trend

1.High-end application expansion with the popularization of WE43, ZK60 and other high-performance magnesium alloy particles, its application in aerospace, military and other high-end fields will be further expanded.

2. Recycling economy regeneration of magnesium alloy particles technology is gradually mature, the future advantages in environmental protection and cost will be more obvious.

3.Regional market growth India, Southeast Asia and other emerging markets for magnesium alloy particles demand is growing rapidly, will become an important growth point in the future.

4.Customized serviceWith the downstream industry's improved requirements for material performance, customized magnesium alloy particles (such as specific particle size and composition) will become mainstream.

Ⅳ. Challenges and risks

1.Raw material price fluctuations magnesium ingot prices are greatly influenced by energy costs, which may put pressure on the production cost of magnesium alloy particles.

2.Technical barriersThe production technology threshold of high-end magnesium alloy particles is high, and small and medium-sized enterprises may face the challenge of technological upgrading.

3. Intensified international competitionWith the increase of global production capacity of magnesium alloy particles, the market competition will be more intense.

V. Investment and strategic recommendations

1.Technology R&DIncrease R&D investment in high-performance magnesium alloy particles (e.g., high-temperature and corrosion-resistant) to seize the high-end market.

2.Market expansion focuses on the layout of India, Southeast Asia and other emerging markets, to establish localized sales and service network.

3. Integration of industry chain extends upstream to control magnesium resources; extends downstream to develop high value-added end products.

4. Environmental compliance layout of regenerated magnesium alloy particles technology in advance to meet future environmental regulations.

Summary

The magnesium alloy pellet market has a broad outlook, with lightweight trend, technological advancement and emerging market demand as the main drivers. In the future, high-end application, circular economy and customized service will become the key direction of industry development. Enterprises need to strengthen technology R&D, market expansion and industry chain integration to cope with market competition and cost pressure.

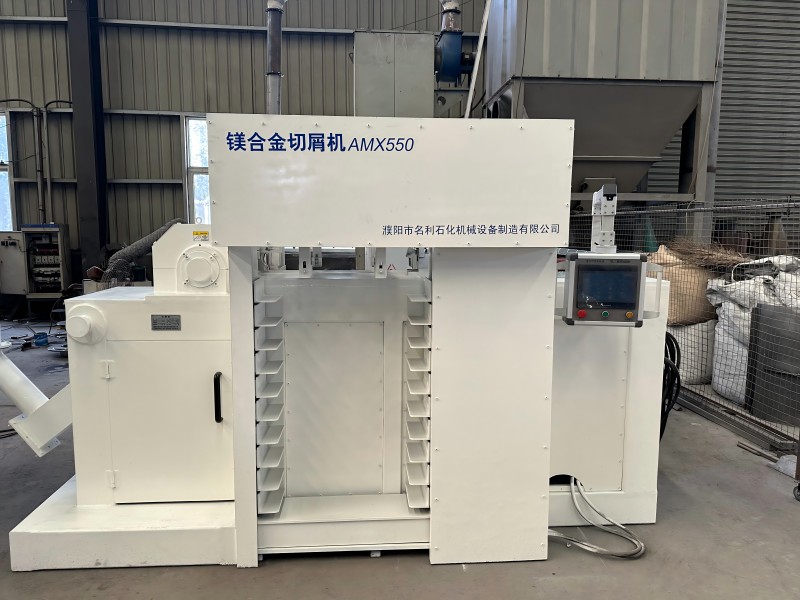

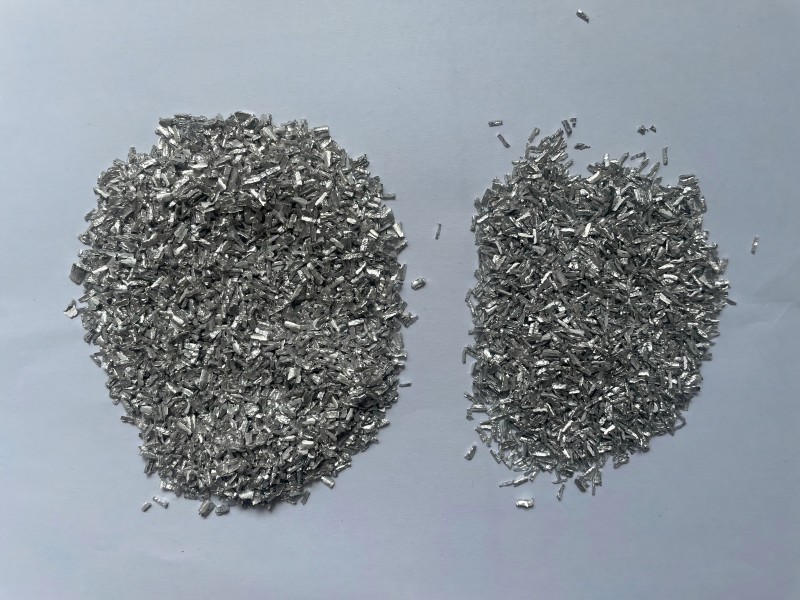

Our machines and products

Keywords

Magnesium alloy ingot pelletizer

Magnesium alloy ingot granules machine

Magnesium alloy ingot granulator

Magnesium alloy ingot chip cutter

Magnesium alloy ingot chip machine

Magnesium alloy granulator

Magnesium alloy cutting equipment

Magnesium alloy particles production line

Magnesium alloy chips production line

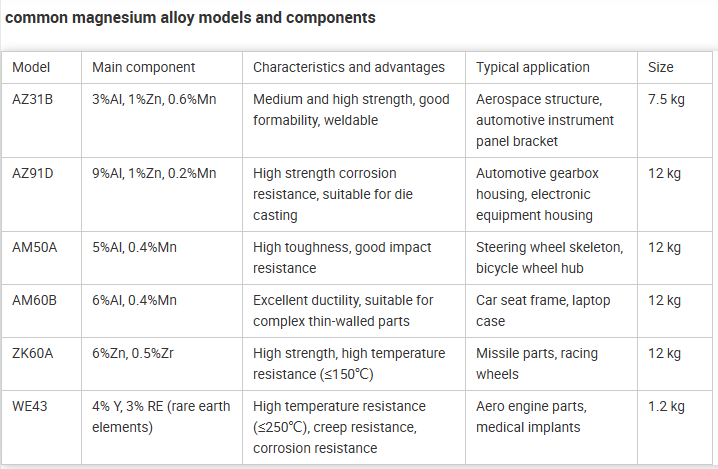

AZ91D AM50A AM60B granules for die casting

semisolid die casting magnesium alloy granules production line